Schooler Cuts Down The Net

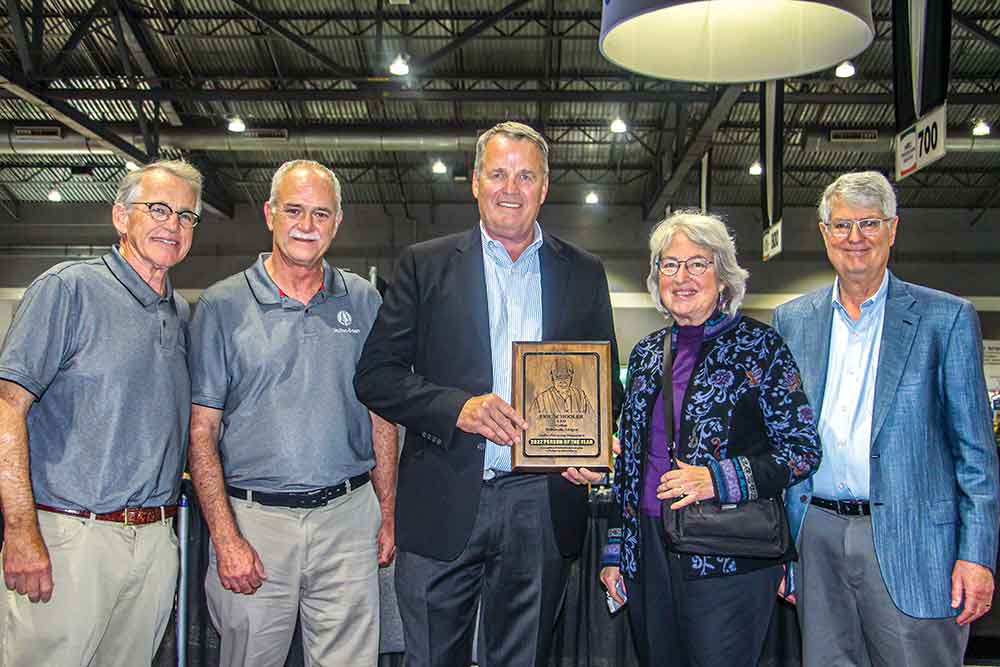

EDITOR’S NOTE: Timber Processing magazine presented its 34th Annual Person of the Year award to Eric Schooler, CEO of Collins, as he prepared to embark on his new career of “retirement.” The presentation ceremony and reception, which was hosted by Hatton-Brown Publishers, Inc. and sponsored by Real Performance Machinery, occurred during the Timber Processing & Energy Expo at the Portland Expo Center in Portland, Ore., and at the Hatton-Brown Media Presentation Center in the middle of the show floor. Timber Processing magazine Editor-in-Chief Rich Donnell delivered opening remarks on the history and evolvement of the award, and Senior Editor Dan Shell spoke about Schooler’s career before presenting the award to Schooler, who received a standing ovation from a packed crowd. Here is Schooler’s acceptance speech:

Thank you to Timber Processing magazine for this special honor as my career winds down. I feel like an ex-ball boy or bat boy that has just joined the big leagues.

I have been coming to the Portland sawmill machinery show my whole career. I haven’t missed many. And I have a full collection of Timber Processing magazines at home.

Longevity goes a long way: In my case 50 GREAT years in this industry—although, there were a few recession years that challenged the heart.

It is truly an enormous honor to represent our industry. Our public reputation has gone up and down. We have been attacked over the years by many, but with the need for housing, climate change, carbon, those same people now recognize this industry as part of the solution!

A lot has changed in my 50 years in the timber industry. Yes, I look older, sometimes I feel older, hair gray, and less of it, etc. Forests are replanted, trees grow faster and straighter and our mills get a lot more lumber or plywood, or EWP out of every tree. Actually, EWP didn’t exist 50 years ago.

1972, my start, at a big high production sawmill, there was not a single computer, no PLCs, no VFDs. Sales orders were typed in triplicate and sent to the mill. That mill had J-Bar sorter #2! It didn’t work well. The rest of the world still had green chains.

My timing was lucky. Crude electronics were showing up. Nobody understood or believed in them. Computers were slow, bulky, expensive, unreliable. The guys on the floor didn’t understand or believe in them.

It was the start of the automation. As a supervisor you worked and maneuvered only as well and as fast as your crew. Technology was moving fast, faster than our industry for sure. There certainly were lots of false steps in the automation evolution. Shadow scanning (edger), feely finger scanners (trimmer), mechanical relays, cart sorters, arc sawing, and on and on: Most worked but were impractical or they were soon outdated by newer technology and ideas.

Now, five decades later we feed values and parameters into computers and they scan, process and operate almost every machine, every decision in the mill. Operators now basically oversee and watch for flow interruptions. The result is more output, fewer line workers, better grade, better working conditions, and maybe most important, more recovery from every log. We learned to rely on those who develop and maintain the computers, scanners, PLCs and automation.

I have had the great fortune to work for incredible people and companies. In my early years I was exposed to supervision in literally all areas of sawmilling, log yard to shipping and on all of the shifts. There is a big picture.

My last 35 years have been a dream. Starting at Hampton Lumber when it was a one mill company, led by John Hampton. And my last 20 years leading the Collins Companies for the amazing Collins Family. Privately held, family businesses are special. I have worked with really great people throughout these two companies. Their respective mottos— “Find a Better Way Every Day” and “Do the Right Thing”—say a lot. I was part of something special.

It has been a fascinating time to work in this business. Every day is the same, and by that I mean always changing. It has been an era of applied technology and always, continual improvement.

As I wind down my career, I will miss the brainstorming, the creative solutions, the teamwork. And I will miss all the many fascinating characters…absolutely wonderful people…and the incredible comradery within this industry.

To you young folks starting out: Work hard, volunteer for everything, ask questions, and at the same time question the answers.

Make responsible choices. Manage time and energy. Nurture relationships and be good stewards to our forests and operations.

I can only imagine what technology and opportunity will bring this industry in your 50 years.

I appreciate this award, a kind acknowledgement for a long career. I wish I could do it all over again.

Again, thank you.

Latest News

Multi-Family Housing Continues Surge

U.S. single-family housing starts in April dipped 7.3% from March to a seasonally adjusted rate of 1.1 million, but multi-family starts (five units or more) shot up 16.8% over March to 612,000, according to the U.S. Census Bureau and U.S. Dept. of Housing and Urban Development monthly new…

How’s Your Log Supply Chain?

Article by Dan Shell, Senior Editor, Timber Processing May 2022 – In between looking for extra employees to fill out another shift or solidify the one or two already in place, or perhaps looking for larger vaults to hold the cash they’ve been putting away thanks to record lumber prices, lumber suppliers would be smart to…

Softwood Lumber Board Updates Board Members

Secretary of Agriculture Tom Vilsack has reappointed George Emmerson, J.D. Hankins II, Brian Luoma and Brad Thorlakson to serve second terms on the Softwood Lumber Board (SLB) Board of Directors. He has also appointed past Director Marc…

PLIB Partners With TP&EE

Hatton-Brown Expositions and Pacific Lumber Inspection Bureau announce that PLIB will participate in the Preferred Partner program with Hatton-Brown’s Timber Processing & Energy Expo (TP&EE), which will be held September 28-30 at the Portland Exposition Center in Portland, Ore…

Pres-To-Logs Has History Of Its Own

Article by Rich Donnell, Editor-in-Chief, Timber Processing April 2022 – The story in this issue on North Idaho Energy Logs, written by David Abbott, caught my attention at the mention of Pres-to-logs. Much of the Idaho company’s success in wood energy markets is because of its energy logs or fire logs composed of…

BC Harvesting Deferrals Kick In

No harvesting will be allowed on nearly 1.7 million hectares (4.2 million acres) of old-growth in British Columbia as the province and First Nations throughout it develop a new approach to sustainable forest management. “Our government’s new vision for forestry is one where we better…

Multi-Family Housing Takes Up Slack For March

U.S. housing starts edged higher in March, increasing 0.3% to a seasonally adjusted rate 1.793 million, according to the U.S. Census Bureau and U.S. Dept. of Housing and Urban Development monthly new residential construction…

Freres Celebrates Centennial Anniversary

Lyons, Ore.-based Freres Lumber Co., now doing business as Freres Engineered Wood, is celebrating its centennial year, marking a century of transformative growth and positive impact on the wood products industry, clients, employees, and its surrounding communities. Freres celebrates this…

Find Us On Social

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.