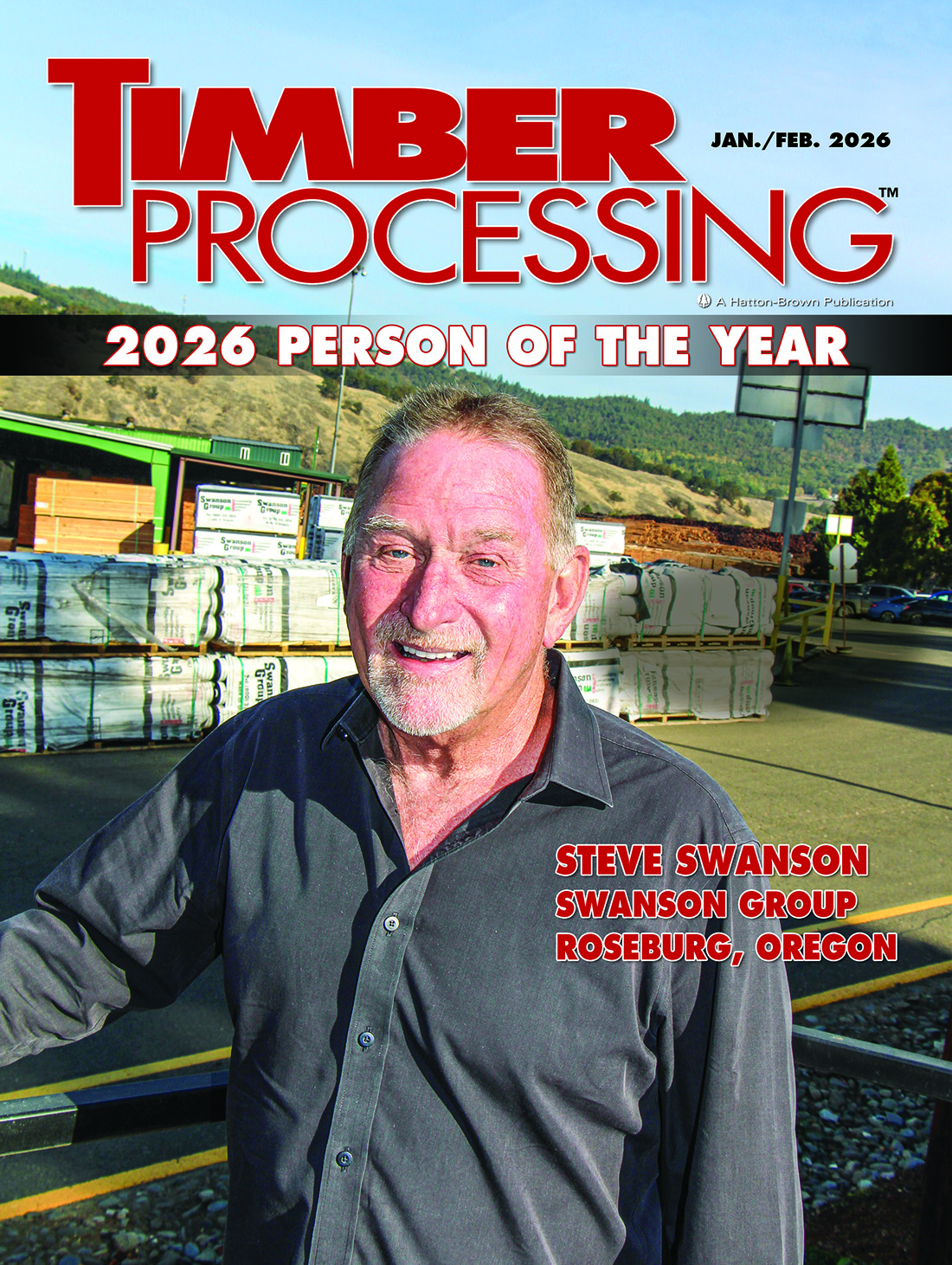

U.S. Lumber Coalition Taps Steve Swanson For Chair, Again

U.S. Lumber Coalition Taps Steve Swanson For Chair, AgainSteve Swanson, CEO & Executive Chairman of the Swanson Group, and recently named the Timber Processing 2026 Person of the Year, has for the second time assumed the role of Chairman of the U.S. Lumber...

Latest News

U.S. Lumber Coalition Pulls No Punches With New Year Statement

U.S. Lumber Coalition Pulls No Punches With New Year StatementSoftwood lumber prices remain at historically low levels. Prices today are 54% lower than their 1975 average and 49% lower than their 1995 average, adjusted for inflation, yet Canada and the National Assn....

Softwood Lumber Board Announces New Appointees

Softwood Lumber Board Announces New Appointees The U.S. Department of Agriculture (USDA) has announced the appointment of six members to serve on the Softwood Lumber Board. These six appointees will serve three-year terms beginning Jan. 1, 2026, and ending Dec. 31,...

Burton Mill Solutions Acquires Southern Saw & Wood

Burton Mill Solutions Acquires Southern Saw & WoodBurton Mill Solutions has announced its acquisition of Southern Saw & Wood, based in Hamburg, Ark. specializing in reconditioning small and large diameter saws, chipper knives, guides, cutting tool design and...

Chinook Forest Partners Acquires South Coast Lumber Co.

Chinook Forest Partners Acquires South Coast Lumber Co.Chinook Forest Partners, a forestland investment manager located in Southwest Oregon, has finalized its acquisition of South Coast Lumber Co. and Pacific Wood Laminates, a Douglas fir sawmill, plywood plant, and...

Find Us On Social

About

Timber Processing

Our publication focuses on sawmill project installations in the softwood and hardwood lumber industry in North America and worldwide. Special emphasis is also given to new product technologies and to the important issues impacting the lumber manufacturing industry.

The Timber Processing editorial staff counts 90 years of combined experience in visiting sawmill operations, interviewing management and production personnel and delivering concise and accurate reports on startups and upgrades.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.

.

.