DECEMBER 2022

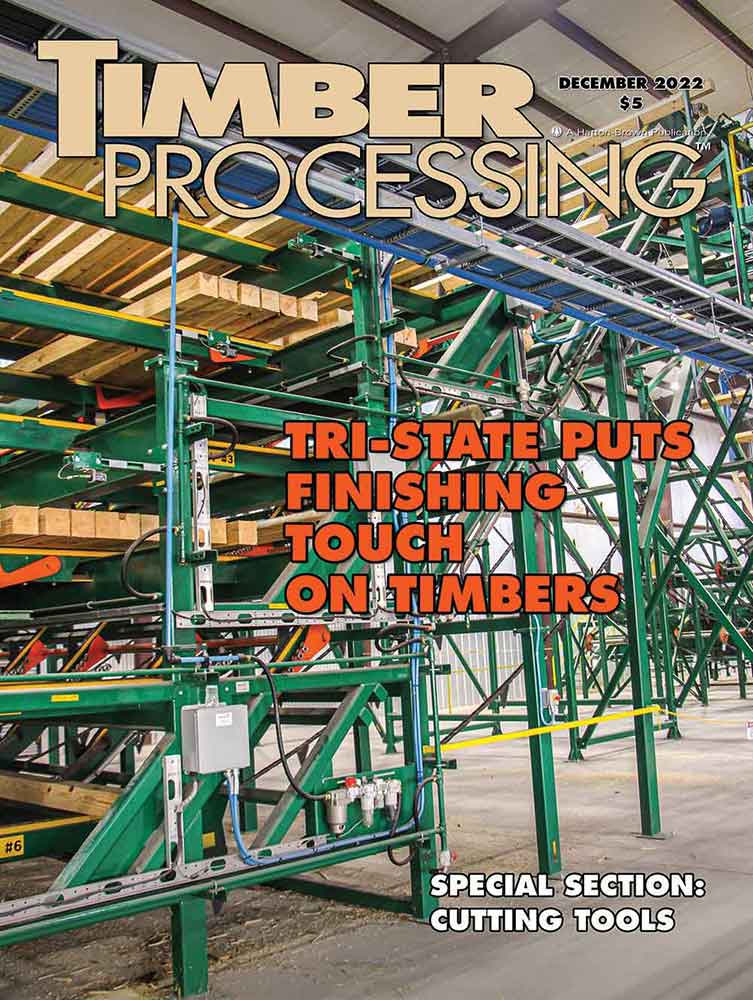

Cover: Tri-State Puts Finishing Touch On Timbers

FULTON, Mississippi – As more and more greenfield and brownfield sawmills dot the landscape of the South, many smaller, independent mills are finding themselves having to get creative to keep up. Some are upgrading equipment, some are selling out, and some are just treading water. But for Tri-State Lumber, part of the Homan Industries family of companies that have been operating in Fulton for 56 years, the answer to competing against the mega-mills is simple: Don’t!

Inside This Issue

THE ISSUES: Filled With Action On Many Fronts

2022 left us with softened lumber process, declining housing starts, and rising interest rates. Nobody was complaining too loudly, given the astronomical surge in lumber prices in the spring of 2022 that everyone enjoyed, and the corresponding surge in housing starts. There remained activity in the building markets at year’s end, but there was shuffling around with lumber production curtailments, while new greenfield or recently upgraded mills became anxious to see what they could do. You might say it was a mixed bag of goods heading into the new year.

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- Arizona Operation Changes Name

- Roanoke Valley Lumber Progresses

- Westervelt Announces Cade Warner As COO

- Eagle Forest Products Purchases Lumber Operation

- Weyerhaeuser, Union Come To Agreement

Don’t Expect, Inspect!

At the Simonds International Tech Center for Saw Filer Vocational Training we utilize a number of slogans or phrases to encourage students to remember to focus on the fundamentals. One of those phrases is “Don’t Expect, Inspect!” Simply loading a saw blade on to a CNC or conventional sharpening machine and pushing the button is no assurance that you will take off a sharp, ready to run blade.

Article by David Purinton, VP Marketing, Burton Mill Solutions

CUTTINGtools

EDITOR’S NOTE: The following companies submitted editorial profiles to complement their advertisements placed in the Timber Processing December 2022 issue.

- Andritz

- BID Group

- Colonial Saw

- Hanchett Mfg.

- Oleson Saw Technology

- Vollmer

- Williams & White

About Roundwood

There has been high-level discussion from some government policymakers in the EU (European Union) about restricting the use of “roundwood” as feedstock for pellet fuel. (Roundwood typically references the part of the stem of a tree that is not sawn into lumber.) While the spirit of policymaking exercise is properly grounded as a tactic to disallow deforestation and encourage the most efficient use of a renewing resource, a blanket exclusion of “roundwood” is misguided. This paper attempts to explain why. This paper also discusses the dynamics of forest growth and carbon sequestration.

Article by William Strauss, President of FutureMetrics

ATlarge

MACHINERYrow

- KDS Partners With New York Blower

- John King Chains Wins MHEA Award

- Carbotech Names Southern U.S. Manager

- Chile’s Foraction Orders Sawmill From USNR

- SmartMill Breaks Into Eurozone

Find Us On Social

Tri-State Puts Finishing Touch On Timbers

Article by Jessica Johnson, Senior Editor, Timber Processing

FULTON, Mississippi – As more and more greenfield and brownfield sawmills dot the landscape of the South, many smaller, independent mills are finding themselves having to get creative to keep up. Some are upgrading equipment, some are selling out, and some are just treading water. But for Tri-State Lumber, part of the Homan Industries family of companies that have been operating in Fulton for 56 years, the answer to competing against the mega-mills is simple: Don’t!

Larry Homan, a sage at 80 years young, says those companies don’t ask him what to do, or give him any control over what they do; so, why take cues from them? Instead, Tri-State stays in its lane, focusing on what it has done well for the last five decades—high quality, treated southern yellow pine backed by good customer service. “We have maintained this philosophy for a long time: Control what you can control. I have control over this mill. We concentrate on this place and what we can do for the better,” Homan says with conviction.

He adds that while the mill he has built from the ground up is fairly small, producing 50MMBF annually, being a specialty mill that cuts only timbers, with the value-added bonus of the ability to cut, kiln dry, surface, spray with anti-mold solution and then treat, has led the company to a strong balance sheet for decades. “Our niche is timbers. We know our place. And we’re going to try to be the best little mill around.”

The path to getting there is where it gets interesting. Homan believes that for dimension lumber, the future is in cross-laminated timber (CLT). But the market will always have a demand for timbers, so in order to keep up with that demand, Tri-State needed to upgrade its facility in a major way. The first major upgrades came in 2016, and haven’t stopped. Homan says his objective with the mill is to grow and try new things. He admits that they aren’t technology leaders, something he is not particularly proud of. But, he knows and understands how valuable technology can be for a mill, so Homan is working to find solutions that fit his needs and budget.

While Homan might not be the leading edge with technology, he does re-invest in the facility he loves so much. “We knew that our planer was a problem; we knew our dryer was a problem. We can’t go out and build a 350MMBF mega-mill. So we are going to do what we can do and pay for. We are going to continue to do that. We’re just trying to do better every day, a little bit at a time.”

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.