AUGUST 2022

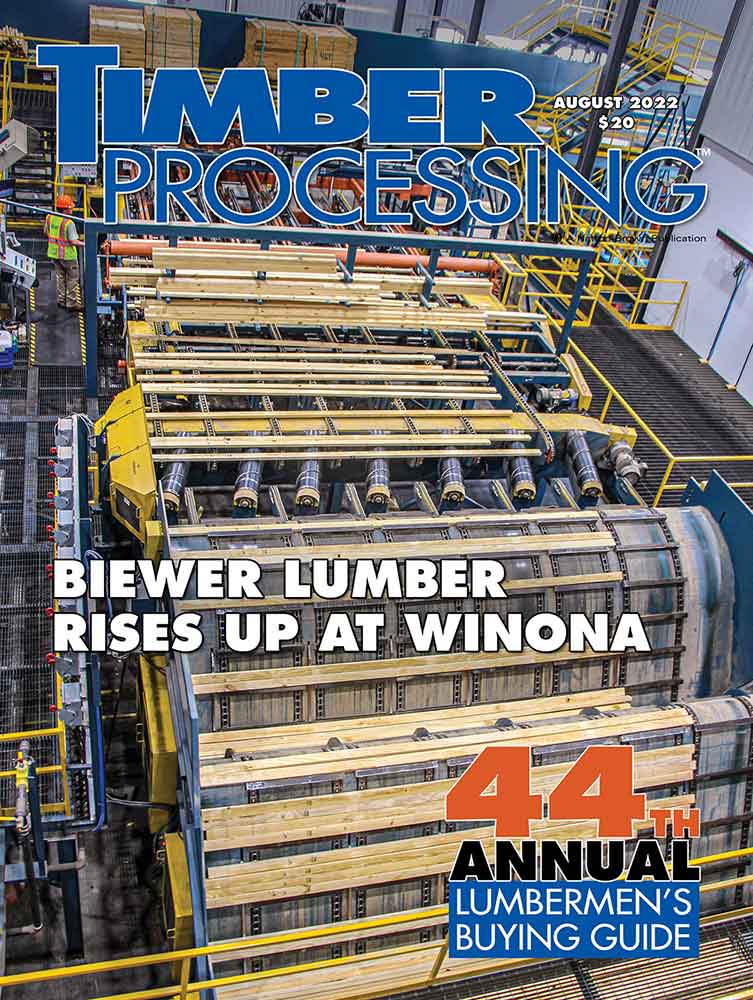

Cover: BIEWER LUMBER RISES UP AT WINONA

WINONA, Mississippi – The Southern sawmill industry has seen many changes through the years; living legends even tell tales of life before the curve-sawing gang and the continuous dry kiln. But perhaps the single greatest change to happen to the industry, especially in the U.S. South, was a little project in Newton, Mississippi. The “little project” brought Michigan-based Biewer Lumber to a new frontier, southern yellow pine.

Inside This Issue

THE ISSUES: You Can’t Miss Big Number 44

You’ll notice on the cover that this issue represents the 44th Annual Lumbermen’s Buying Guide. I knew we were putting another Buying Guide together but it didn’t really make its presence felt until I saw the number 44 on the cover proof before it went to press.

I’ve always been impressed by the number 44, mostly from an athletics standpoint. If you’re an old baseball fan, you’ll recall that Hank Aaron wore number 44, so did Willie McCovey of the Giants and Reggie Jackson of the Yankees. The great basketball player, Pete Maravich, also wore 44 and today it hangs from the rafters of the Atlanta Hawks arena.

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- STP-Tolko Plans Ackerman Upgrade

- PalletOne Buys Half Of Dempsey

- Paper Excellence Purchases Resolute

- Teal Jones Digs Into Louisiana

- Pacific Woodtech Purchases LP EWP

- D.R. Johnson Has Prairie City Running

- USNR Acquires Timber Automation

TP&EE Includes Two Conferences

Timber Processing & Energy Expo, which will be held September 28-30 at the Portland Exposition Center in Portland, Oregon, will include two conferences: Sawmill Productivity & Efficiency; and From Forest to Frame: Mass Timber Developments.

2022 Lumbermen’s Buying Guide: Products/Services/Supplies

The Lumbermen’s Buying Guide, presented in Timber Processing August 2022, is your guide to over 350 forest products industry equipment manufacturers, suppliers and service businesses and their products.

ATlarge

- Longtime Sawmill Technician Passes

- WWPA Partners With TP&EE

- PLIB Hires Technical Services Director

- WWPA Moves HQ To Lake Oswego

- Hardwood Coalition Launches Website

Find Us On Social

Biewer Lumber Rises Up At Winona

Article by Jessica Johnson, Senior Associate Editor, Timber Processing

WINONA, Mississippi – The Southern sawmill industry has seen many changes through the years; living legends even tell tales of life before the curve-sawing gang and the continuous dry kiln. But perhaps the single greatest change to happen to the industry, especially in the U.S. South, was a little project in Newton, Mississippi. The “little project” brought Michigan-based Biewer Lumber to a new frontier, southern yellow pine. But perhaps the bigger leap was the announcement that BID Group was going to provide a turnkey installation of the entire plant, from gate to gate. Biewer had partnered solely with BID to provide equipment.

That’s when the floodgates opened in the U.S. South. If you’ve built or thought about building a SYP mill with BID Group, you’ve toured Biewer Newton, or maybe you’ve spoken with Biewer General Manager Dan Bowen. This magazine covered the Newton project extensively. It is the original blueprint, the OG as the kids would call it. So, for Bowen and Biewer Lumber owner (and 2017 Timber Processing Person of the Year) Tim Biewer, what do you do for an encore? You’ve changed the landscape of SYP manufacturing. The natural next step could be to build another monster-sized BID Group sawmill in Mississippi and change it up, in small tweaks and changes, here and there, to get even more added capacity.

That’s exactly what they did with Biewer Sawmill Winona. It sits northwest approximately two hours from the trailblazing Newton site. The Winona site went from cotton fields to a high capacity, high-tech sawmill in less than 18 months. That’s a major benefit of being independently owned, Mill Manager (and Tim’s youngest son) Blake Biewer says: “We have the ability to make decisions quickly. We knew we wanted to build, we had toured potential sites, and within a month picked Winona and had a PO issued to BID in December 2020.”

Biewer says that he and Bowen looked at several locations throughout the Southeast. They had focused primarily on Mississippi, before eventually landing on the north central region in Winona. Winona’s draw was the good timber growth to drain ratio, rail access to Memphis, and the site’s access to natural gas for the kilns. A close proximity to Newton means staff can easily move between the two mills. Information-sharing and general support are critical during startups, as well as other training synergies, Biewer adds.

The mill sits on about 100 acres, with the process slightly more spread out than its predecessor, with just a few tweaks to the overall layout. Over the years, Biewer had discovered what worked well in Newton. They had included capital expenditure projects that were done in Newton from the start in Winona, almost making a carbon copy of the Newton mill—with the exception of moving the layout around to have all residual bins in one area, and also adding two radial cranes from Fulghum next to each other on the log yard. “The processes we do at both mills are exactly the same,” Biewer says. “We know what works for us.”

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.