APRIL 2023

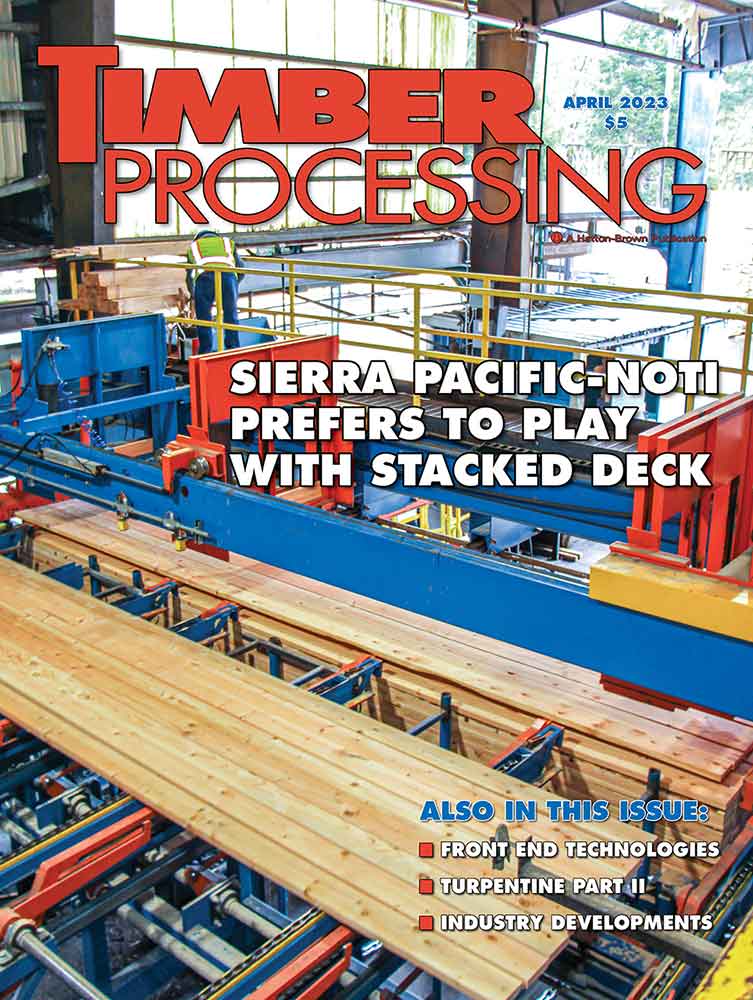

Cover: Sierra Pacific-Noti Prefers To Play With Stacked Deck

NOTI, Oregon – Recent improvements at Sierra-Pacific’s Noti mill 25 miles west of Eugene, Oregon have boosted efficiency and quality at the facility that produces all-green, 100% Douglas fir products, primarily dimension lumber along with timbers.

Inside This Issue

THE ISSUES: Aging Like A Fine . . . Sawmill?

Often I wonder what the future holds. I close my eyes and try to think 10, 15, 20 years down the line—30 years seems like a lifetime. Right now, in this moment, I’m a young mom, with young kids. I am in the thick of long nights at the ballpark and practicing spelling words in the car. It’s hard to think about that in 30 years, my perfect little boys will be older than I am currently. Likely they will have families of their own and little ones of their own who for some astonishing reason can drink three gallons of milk per week without a care in the world.

When I gaze into my crystal ball it is hard to see what is coming down the line. Does the sawmill of the future have digital twins for every machine, like Tesla cars? That sure would make for an interesting maintenance call wouldn’t it?

Article by Jessica Johnson, Senior Editor, Timber Processing

NEWSfeed

- Vaagen Thankful For Support

- Mercer Gains CLT Contract

- Canfor Report Mirrors Industry

- Forisk Reveals Top 10 Producers

- Georgia-Pacific Contributes To CLT Project

- New Pellet Mills Eye Sawmill Byproducts

- Dillard Lumber Wins Roseburg Safety Award

FRONT END

EDITOR’S NOTE: The following companies submitted editorial profiles to complement their advertisements in Timber Processing April 2023.

- BID Group

- BM&M Screening Solutions

- Brunette

- Cooper Machine

- FiberPro

- John King Chains

- Linden

- Mebor

- Mellott Manufacturing

- Metal Detectors Inc.

- Sennebogen

- USNR

Rise And Fall: The History Of Turpentine

Second of Three Parts

A major breakthrough in the naval stores sector occurred around 1902 when University of Georgia chemist Charles Herty designed and patented the cup-and-gutter gum collection system, a big improvement over the traditional box (cavity) method. Herty’s invention was less intrusive and thus helped prolong tree life while making gum collection easier, faster, cleaner and less wasteful.

Article by DK Knight, Editor/Publisher Emeritus

MACHINERYrow

- Northcentral Technical College Produces Band Saw Filer Program

- Cooper Machine Partners With EWD

- Con-Vey Names Buck As Product Manager

- Canfor DeRidder Has Log Cranes In Place

ATlarge

- Homan Industries Names Reaves CEO

- Search North America Adds Rupp As Senior Recruiter

- Hunt FP Supports Forest Products Center

- Roseburg Enhances Executive Team

- Cal-Tex Lumber Purchases MiCROTEC System

- McDonough Acquires New Brunswick’s B.I.D.

- Hampton Gets Busy With The Bees

- Hancock Lumber Expands Executive Team

Find Us On Social

Sierra Pacific-Noti Prefers To Play With Stacked Deck

Article by Dan Shell, Senior Editor, Timber Processing

NOTI, Oregon – Recent improvements at Sierra-Pacific’s Noti mill 25 miles west of Eugene, Oregon have boosted efficiency and quality at the facility that produces all-green, 100% Douglas fir products, primarily dimension lumber along with timbers.

During the past four years, the mill has added a new Lucidyne (now owned by Microtec) grade scanner, new USNR trimmer infinite fence system and most recently a Hogue Industries high speed dual fork stacking line with end-tamping feature. A Samuel strapping system with innovative batten feeding feature was added to the line shortly after.

The mill’s finishing end had been bottleneck for the operation, says Mill Manager John Simington, adding that improvements in the area the past few years—grader, fence and new stacking-strapping line—have boosted overall efficiency.

The largest of the projects included an all-electric Hogue Industries high speed dual fork stacker with secondary hoist system and Samuel strapping system. The project helped speed up the planer mill and added more precision and efficiency on the stacking-strapping end, contributing to a 25% overall increase in stacking capacity.

Simington says he really likes the indexing and sequencing features of the stacker’s control system, which also allows pre-programming for every individual product the mill stacks.

“The previous stacker would take up to a minute and a half for each package,” Simington says. “But this unit will do it in 47 seconds.” He adds that the secondary hoist that takes the first few courses of a unit while the primary hoist cycles down to exit a full unit has helped speed up throughput at the planer even more.

The Samuel strapping system including batten feeding and strapping was a significant upgrade, Simington says, because it automated a process that had formerly been done manually by forklift drivers, resulting in a win for the mill on several levels.

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.