March 2023

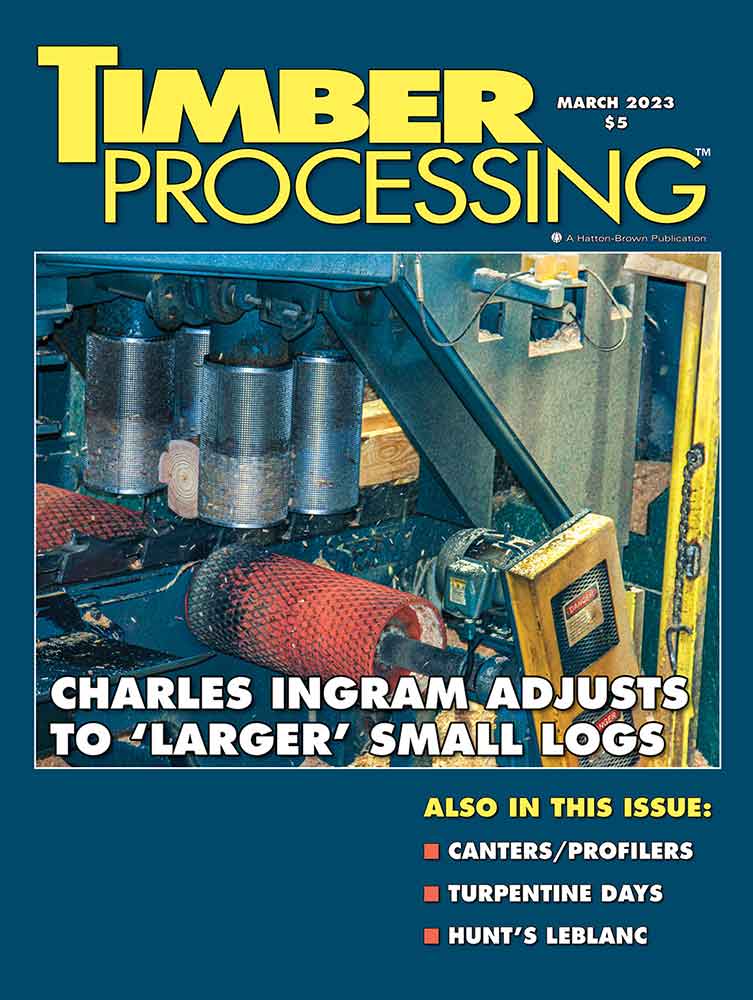

Cover: Charles Ingram Adjusts To ‘Larger’ Small Logs

EFFINGHAM, South Carolina – Achieving success is difficult enough in the first place; maintaining it over the long haul can be even trickier. To do so, businesses often find it necessary to adapt to changing conditions, make adjustments, alter strategies. What worked yesterday may not be right for today, and knowing when to change can be critical.

Inside This Issue

THE ISSUES: Your Tax Dollars Not At Work

You may be aware of our affiliate magazine, Panel World, which covers the structural and non-structural wood panel industries in a similar way that Timber Processing covers the lumber industry. Recently in Panel World we ran a news article on Huber Engineered Woods pulling out of a long-planned project to build a $440 million oriented strandboard (OSB) plant in Cohasset, Minnesota, which would have been Huber’s sixth OSB plant following ongoing operations in Maine, Georgia, Virginia, Tennessee and Oklahoma.

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- Sierra Pacific Industries Announces New Sawmills

- Canfor Plans New BC Facility

- Coalition Favors Duty Upgrade

- Structurlam Looks To Reboot

- Mendocino Companies Expands In Utah

- Sawmill In Camden Has New Life

- Court Halts Logging Plan

- Frank Bennett Was a Visionary

- Oregon Forest Industries Council Says Oregon Department of Forestry Messed Up

CANTERS PROFILERS

EDITOR’S NOTE: The following companies submitted editorial profiles to complement their advertisements in Timber Processing March 2023.

- Andritz

- BID Group

- Cone-Omega

- Mebor

- Optimil

- USNR

Naval Stores Back When

First of Three Parts

It was dirty, demanding, and destructive, a remarkable forest-based industry that endured for most of three centuries and even today is survived by a distant remnant. It was a major component of the South’s economy, but it wiped out untold volumes of longleaf and slash pine timber and scarred the lives of many who toiled at the tasks it entailed. And, in some instances, it left a shameful wake of social wrongdoing. When wooden ships and boats were the thing, tar and pitch were essential in keeping them seaworthy, as they excelled in keeping vessels watertight, preventing shipworm infestations, and preserving rigging. Tar and pitch were know as ‘naval stores,’ a term that eventually included turpentine and rosin.

Article by DK Knight, Editor/Publisher Emeritus

Forest Health Project

JOHN DAY, Oregon – Forest health issues continue to dominate the concerns of Western U.S. forest managers, especially on huge expanses of public lands that are in dire need of management activities that reduce the potential for disastrous wildfires. With huge backlogs of forest health projects and traditional funding sources running thin, stewardship contracts offer national forest managers the opportunity to integrate revenue-producing timber harvests with landscape-scale forest health and restoration activities and accomplish goals that benefit a variety of forest interests and stakeholders.

Article by Dan Shell, Senior Editor, Timber Processing

Hunt Moves Forward With LeBlanc

EDITOR’S NOTE: The question-and-answer session with Richie LeBlanc, president and CEO of Louisiana-based Hunt Forest Products, LLC, also appeared in the March issue of Panel World, an affiliate of Timber Processing.

Family-owned Hunt Forest Products named LeBlanc as president in 2016. After a stellar college baseball career as a pitcher for Louisiana Tech, and several years pitching in the minor leagues for the Kansas City Royals, LeBlanc wrapped up his business degree at La Tech and worked with an insurance agency as vice president in Ruston for 10 years, before joining Willamette Industries in Ruston and then Weyerhaeuser after Weyerhaeuser acquired Willamette in early 2002 following a prolonged takeover battle. LeBlanc served on the integration team, charged with merging cultures of Willamette and Weyerhaeuser. He became the land adjustment program manager of Weyerhaeuser’s North Louisiana timberlands organization. In 2015, he was named director of U.S. real estate operations for Weyerhaeuser, before joining Hunt Forest Products.

MACHINERYrow

- Esterer WD Reveals New Bold Logo

- McDonough Names Hawley Senior VP

- Doosan Changes Name To DEVELON

- Con-Vey Promotes Goebel To VP

- Büttner Expands Product Range

ATlarge

- Brett Paved Way For Hatton-Brown Abroad

- RoyOMartin Goes Back 100 Years

- Local Hires Strengthen Roanoke Valley Lumber Weldon Team

- Campbell Global Adds Timberland In South

Find Us On Social

Charles Ingram Adjusts To ‘Larger’ Small Logs

Article by David Abbott, Senior Editor, Timber Processing

EFFINGHAM, South Carolina – Achieving success is difficult enough in the first place; maintaining it over the long haul can be even trickier. To do so, businesses often find it necessary to adapt to changing conditions, make adjustments, alter strategies. What worked yesterday may not be right for today, and knowing when to change can be critical.

Charles Ingram Lumber Co., Inc., has displayed this capacity more than once through the years. The southern yellow pine producer operates two separate sawmills on opposite ends of the same property here. Once side processes large logs, while the other is devoted to smaller logs (they call it the Willow Creek mill). Charles Ingram Lumber originally added the small log line in the early 2000s in response to a glut of pulpwood in this region.

“We were having trouble getting rid of pulpwood off some tracts we had bought,” recalls Jesse Moore, who at the time was a forester for Charles Ingram and now oversees mill production. “We built this small log mill to try to capture a super pulpwood type of tree. And it worked well for about 10 years. Then the glut was gone, and competition for that wood started getting a lot stronger from the paper mills.”

Paper mills surround the Charles Ingram facility on all sides. As competition for smaller diameter trees grew extremely tough, the company was forced to make a choice: a big investment aimed at adjusting to a “larger” smaller log, or shutting the Willow Creek line down.

“Fortunately, the lumber market after COVID allowed us to fix the problem,” Moore says. In an effort to continue operating the Willow Creek mill, Charles Ingram Lumber reinvested in much needed upgrades.

“I was a forester for a long time and saw first hand how quickly the resource changes,” Moore says. “It was fast. So we pivoted, we reinvested a lot of money to get it right.”

The solution was fairly obvious: The small log line just didn’t need to be quite so small anymore. In fact some of the butt cut logs were being taken from the small side over to the large log mill. “We don’t have the glut of super pulpwood material, but we also don’t have the large logs anymore either,” Moore states. “It is somewhere in between. So this (setup) fits the log resource we now have.”

He says they don’t do titles here, but Moore, a forester who once served as procurement manager now helps manage day-to-day operations and production at Charles Ingram Lumber, while Thomas Brodie focuses on regulatory and financial management as well as quality control for the family-owned operation in business since the 1930s. In senior management are Jim Anderson (production) and Thomas’ father Furman Brodie (regulatory/financial).

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.