DECEMBER 2020

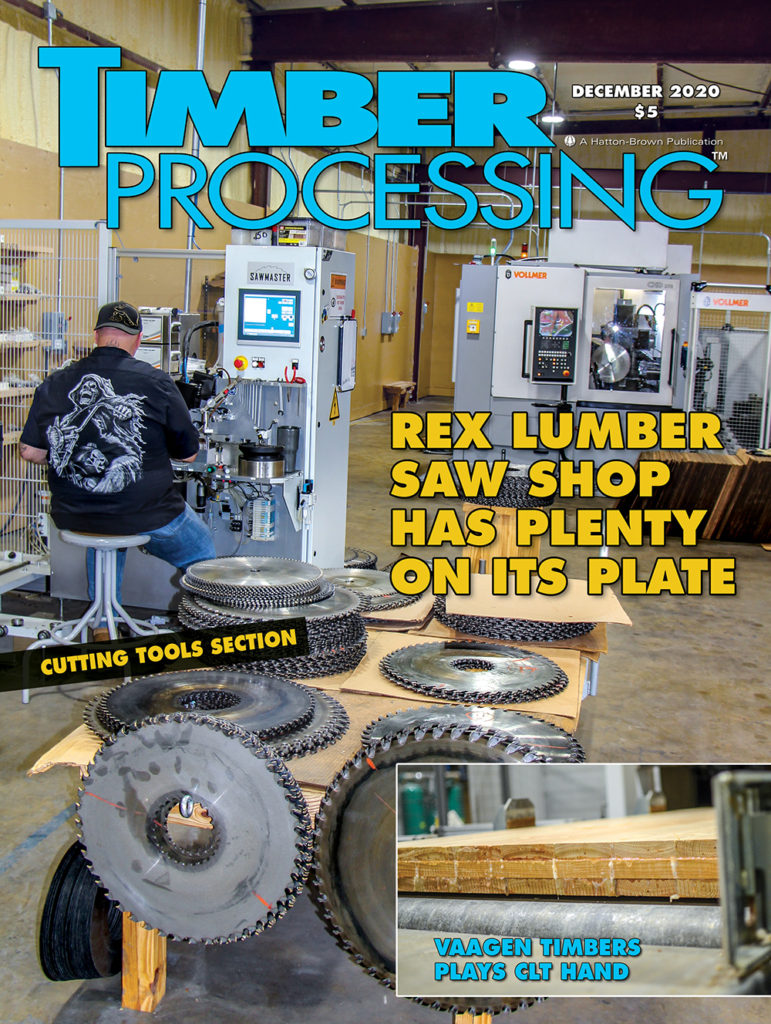

Cover: Rex Lumber Saw Shop Has Plenty On Its Plate

DOTHAN, Alabama – Circle sawing performance and filing efficiency at Rex Lumber are benefiting from a central filing room system that services and works up round saws running at multiple machine centers from the company’s three sawmills in Graceville and Bristol, Florida, and Troy, Alabama.

Inside This Issue

The Issues: Somebody Fix My Rearview Mirror

Many best laid plans went astray in 2020, most noticeably in the event industry. But other than a couple of months when the nation went into lockdown in the late spring, the forest products industry, once it was deemed to be “essential” in the grand scheme of things, picked up the pace and didn’t slow down through the remainder of the year. The catapult was six consecutive months (and counting) of increased housing starts, which ultimately topped 1.5 million in October.

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- Third Quarter Rained Dollars

- Klausner-Enfield Deal Is Near

- Northwest Hardwoods Reconfigures

- Northwest Fire Numbers Are Staggering

- Stoltze Timber Plans CLT Facility

Making The Leap

COLVILLE, Washington – Coming from a long line of sawmillers, and himself once firmly entrenched in the family lumber business, Russ Vaagen recalls when he first approached his dad, Duane, about making a move into mass timber production. It was a positive though not necessarily an all-in conversation, as Duane’s sights were set more on putting the company into a strong financial position for the next generation rather than taking a risky run into cross-laminated timber, an engineered lumber product in its infancy in North America.

Article by Jessica Johnson, Senior Associate Editor, Timber Processing

CUTTING TOOLS

EDITOR’S NOTE: The following companies supplied editorial profiles and images to complement their advertisements in the Timber Processing December 2020 issue:

- Andritz Iggesund Tools

- BID Group

- California Saw & Knife Works

- Colonial Saw

- Ledinek

- Oleson Saw

- Saw-ADD

- SERRA (Wintersteiger)

- Sharp Tool

- Simonds International (Burton Saw)

- Williams and White

- Wood-Mizer

- Smith Sawmill Service

PART 3: The Planer – Ultimate Guide To Moisture Control

Once kiln-dried lumber reaches the planer, mills have one final opportunity to optimize board moisture before their product is sent to customers. Today, using advanced moisture-sensing technologies, mills can utilize their planer to improve overall productivity, enhance grade recovery and reduce, or even eliminate, wet claims.

Article supplied by Finna Sensors and written by Stuart Harries.

Next issue: Part 4: The Sawmill

MACHINERYrow

- VDMA Names New Chairman

- MINDA Forms North America Operation

- Ligna Changes 2021 Show Dates

- Tebulo Becomes Radian Robotics

PRODUCT SCANNER 10

- Sawmill Camera

- Dust Collector

- Light Curtain

- Drying Technology

- Timber Scale

ATlarge

- RoyOMartin Women In Manufacturing

- Gerald Ort Dies At 85 In Wisconsin

- Herron Joins Roseburg’s Strategic Business Team

Find Us On Social

Rex Lumber Saw Shop Has Plenty On Its Plate

Article by Dan Shell, Senior Editor, Timber Processing

DOTHAN, Alabama – Circle sawing performance and filing efficiency at Rex Lumber are benefiting from a central filing room system that services and works up round saws running at multiple machine centers from the company’s three sawmills in Graceville and Bristol, Florida, and Troy, Alabama. Situated in a former warehouse in a rail spur facility that the company is using to build rail shipments, the filing operation is part of the new Troy sawmill investment, with both mill and filing facility starting up in early 2019.

The central filing facility handles roughly 180-200 circle saws daily, from all three mills. In addition to the almost 1,000 saws reworked weekly, the facility will also produce 75-100 new saws per week as well.

“I can’t say enough about our guys and the quality work they do,” says Jeff Burgess, saw shop supervisor who’s been with Rex Lumber four years and was at the Graceville mill before moving to the central filing shop.

Want More Content?

Timber Processing magazine is delivered 10 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.