OCTOBER 2021

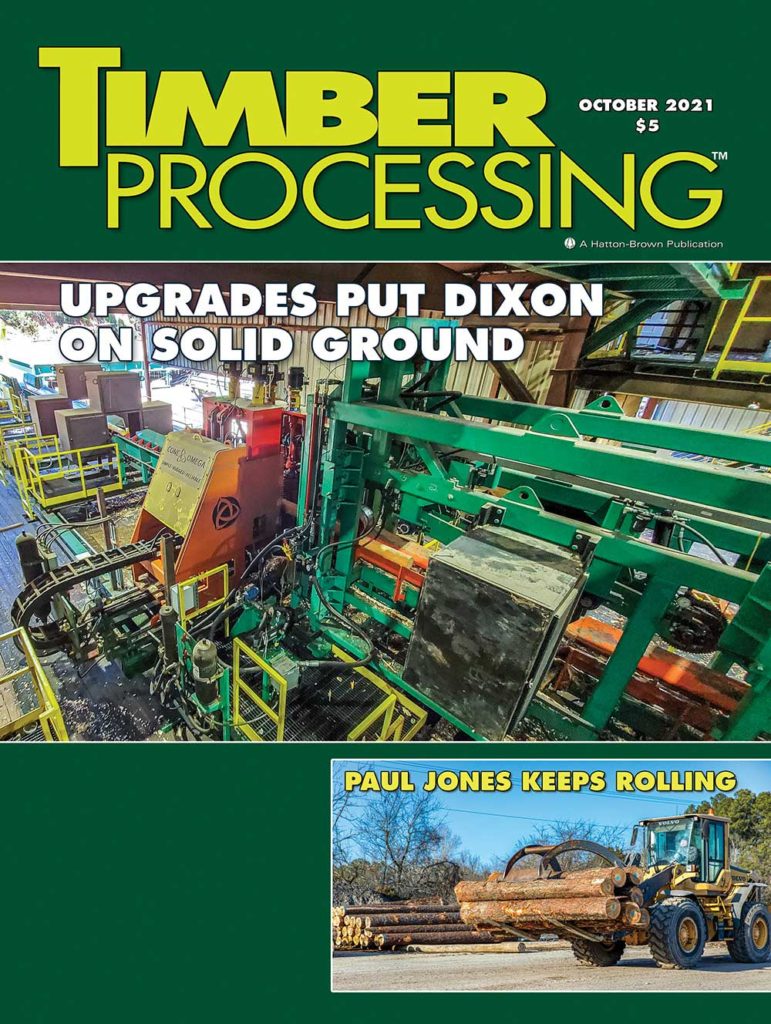

Cover: Upgrades Put Dixon On Solid Ground

EUFAULA, AL – M.C. Dixon Lumber Co. reinvented itself twice this past decade – first as a matter of survival and second to remain competitive.

Initially navigating the 2008 financial crisis and a two-year shutdown/conversion to a small log line for mostly timbers production, Dixon Lumber more recently modernized its planer mill and sawmill while eclipsed by a global pandemic and the hottest markets in the history of the softwood lumber business.

Inside This Issue

THE ISSUES: FOREST SERVICE ‘REASSESSMENT’ RUNS FIRE RISK

Perhaps it was the 20-year lifespan of the contract, or maybe it was yet another fire season that scorched half a million acres in the state: What if we can’t deliver the timber that we promise? What if there are court cases? What if a big chunk of it just burns up? In mid-September, in the midst of yet another smoky fire season, with a groundbreaking 20-year Phase 2 project contract award announcement in the offing after almost two years of delays, officials with the U.S. Forest Service’s (FS) 4 Forests Restoration Initiative (4FRI) in Arizona instead announced a resounding: Let’s re-think this.

READ MORE SOON

Article by Dan Shell, Senior Editor, Timber Processing

NEWSFEED

- FS Cancels 4FRI Phase 2

- New Life Starts Up EWP Operation

- Idaho Forest Group Is Closing Tricon Timber

- Biewer-Winona Coming Along

- Softwood Lumber Board, USDA Enhance Collaboration

- Western Forest Products Has Positive Outlook

MANY LIFETIMES

SNOW HILL, Md. – Of late, Kenny Pusey, President of Paul M. Jones Lumber Co., has found himself sharing a simple observation with his wife: “I tell her we are looking more through the rear view mirror than the front windshield now.” That may be true – they’ve spent most of their adult lives at the mill, and raised their children there. But the company, which traces its roots back more than a century, undoubtedly still has a lot of road left in front of it. The fourth generation, already in place, will see to that.

Article by David Abbott, Senior Associate Editor, Timber Processing

OPPORTUNITY FOR NA SAWMILLS

Ledinek began assembly of the CLT line for the Canadian company Element5 at St. Thomas, Ontario in August 2020, after the outbreak of the COVID-19 pandemic. Despite the unforeseen challenges arising from the pandemic, the highly automated, state-of-the-art manufacturing CLT line was installed, commissioned and certified on the project’s originally projected timeline.

Article submitted by Ledinek.

GLOBAL MACHINERY

EDITOR’S NOTE: The following companies supplied editorial profiles and images to complement their advertisements in the Timber Processing October 2021 issue:

- BID GROUP

- MÜHLBÖCK

- PRINZ

- TS MANUFACTURING

- USNR

ANTHONY HAS SOLID GRIP ON LOGS

BEARDEN, Ark. – It’s another hot and humid summer in Bearden. A fresh load of logs has just arrived at the Anthony Timberlands sawmill facility. A Doosan DX380LL-5 log loader operator eagerly awaits its entry.

Article submitted by Doosan Infracore North America.

NEW POSITION SYSTEM ENHANCES RESAW

Salem Equipment also found the software tools that accompany Delta RMCs made development and deployment remarkably easy. Delta’s pre-installed tools and plots streamlined troubleshooting, including providing an event log to see step by step how RMC handles PLC instructions.

Article submitted by Delta Computer Systems and Salem Equipment.

PRODUCT SCANNER 10

- LOG MERCHANDISER

- JDLINK PLATFORM

MACHINERY ROW

- John Deere, Hitachi End Joint Venture

- Microtec Collaborates With Japan’s Suzuko

- Binderholz Implements Solutions From Trimble

- Neiman Continues Upgrades At Gilchrist

- Hyundai Integrates Doosan Infracore

- Power Equipment Adds Komatsu In Arkansas

- Acquisition Merges Nortrax, Schmidt

ATlarge

- Westervelt Strengthens Management Team

Find Us On Social

Upgrades Put Dixon On Solid Ground

Article by Patrick Dunning, Associate Editor, Timber Processing

EUFAULA, AL – M.C. Dixon Lumber Co. reinvented itself twice this past decade – first as a matter of survival and second to remain competitive. Initially navigating the 2008 financial crisis and a two-year shutdown/conversion to a small log line for mostly timbers production, Dixon Lumber more recently modernized its planer mill and sawmill while eclipsed by a global pandemic and the hottest markets in the history of the softwood lumber business.

The nearly $30 million capital expenditure was spilt into two phases, beginning in June 2019 with the planer mill renovation that included a six-roller Miller (BID Group) planer, then revolving to the sawmill enhancement with a Cone-Omega profiling canter sideboard chip-n-saw line, which was completed in July 2021.

Bob Dixon, Jr., president, engaged several equipment suppliers under the umbrella of Timber Automation.

“We engaged Timber Automation for the turnkey project, bought some of our handling equipment from Baxley and the line came from Cone-Omega. Optimization came from Nelson Bros. and VAB. SmartMill provided some equipment as well,” Dixon says. “We’re happy with every bit of it.”

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.