May 2024

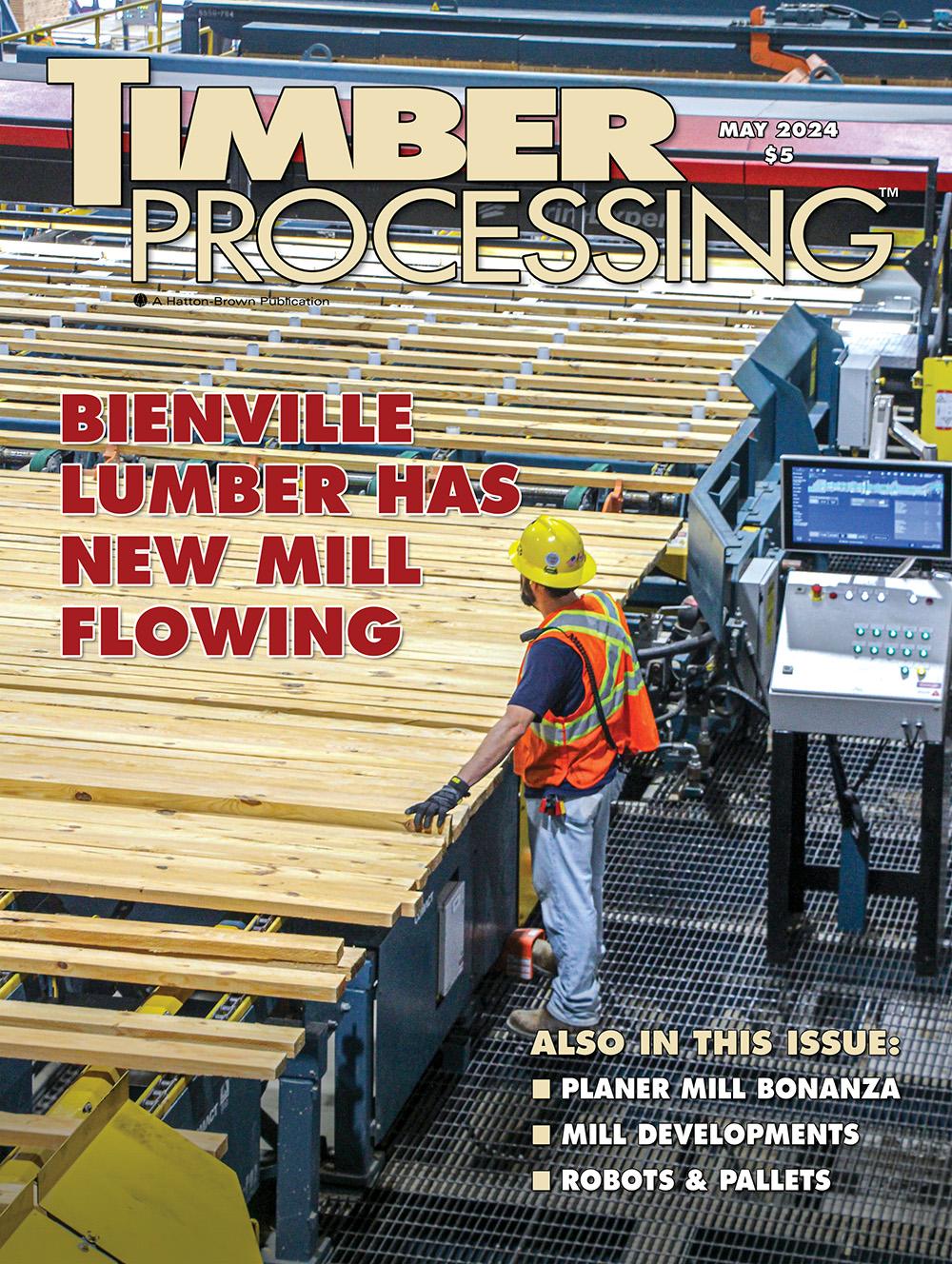

Cover: Bienville Lumber Has New Mill Flowing

The new Bienville Lumber sawmill (i.e. Hunt Forest Products and Tolko Industries) is finding its groove in Taylor, La.

Inside This Issue

THE ISSUES: Not The Ending We Like To Write

Obviously it’s not as personal to us as it is to the ownership, employees and families directly impacted, but the editors here at Timber Processing do take it personally, and feel their pain, when independent lumber operations announce they are going out of business. Unfortunately, it seems like such developments have picked up in frequency as of late, especially in the Northwest, causing us older editors to remember the 1990s when independents were going out with regularity, thanks to the federal government pulling the timber harvesting rug out from under them. I remember making one long trip to the Northwest in the late 1980s and visiting family lumber operations in Oregon run by the Cones, the Ellingsons and the Hanels. They saw the writing on the wall.

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- Industry Losing C&D Lumber

- Collins Sues PG&E Over Dixie Fire

- Two Rivers Plans Second Sawmill

- Georgia Ports Prepares For Growth

PLANER MILL Bonanza

- Bid Group

- Delmhorst

- Finnos

- Gilbert

- Hogue Industries

- Mid-South Engineering

- Murray Latta Progressive Machine

- Samuel Coding & Labeling

- USNR

AT Large

- WWPA Recognizes Grading, Safety

- Roseburg Names Ramm To Lead Manufacturing

- Patrick Lumber Hosts St. Pat’s Open House

- Hancock Completes Log Procurement Team

MACHINERY Row

- Åsljunga Pallen Upgrades Sorting, Stacking

- Canopy Puts New Spin On Automation

- Vollmer Names Böhm As Managing Director

- Richmond Show Finds New ‘Digs’

PRODUCT Scanner 10

- Moisture Sensors

Find Us On Social

Another For Hunt

Article by Jessica Johnson, Senior Editor, Timber Processing

Taylor, La. — Less than one hour down Interstate 20 from the Hunt Forest Products corporate office, and a little less than two hours away from its LaSalle Lumber joint-venture sawmill with Tolko Industries, sits Taylor, an old sawmill town. Hunt saw a huge opportunity in a 240 acre brownfield site to once again go with turnkey technology provider BID Group and sales marketing partner Tolko to form Bienville Lumber—a two-line sawmill whose kiln capacity is a monstrous 400MMBF.

Taylor, La. — Less than one hour down Interstate 20 from the Hunt Forest Products corporate office, and a little less than two hours away from its LaSalle Lumber joint-venture sawmill with Tolko Industries, sits Taylor, an old sawmill town. Hunt saw a huge opportunity in a 240 acre brownfield site to once again go with turnkey technology provider BID Group and sales marketing partner Tolko to form Bienville Lumber—a two-line sawmill whose kiln capacity is a monstrous 400MMBF.

Once the PO was signed, there was no slowing down. Hunt President Richie LeBlanc says the key to the success of this startup has been the learnings from LaSalle, which was the third or fourth of the BID turnkey model to be implemented across the U.S. South. He also points to an incredibly strong and trusting relationship with BID Group.

There’s a familiarity between all the players involved here—Hunt, Tolko, BID, and engineering firm HGA, which acts as project manager and owner representatives both for LaSalle and Bienville. “LaSalle was a successful project,” LeBlanc reiterates, while adding that BID has “matured” a lot since those early days at LaSalle, continuing to enhance its AI capabilities as well as real-time production and operations solutions.

“Alistair Cook (president/CEO) is as good as they come, as is Gaither Holley (construction) and Travis McDonald (integrated solutions). Daniel Gignac (projects) has been a huge help to us,” LeBlanc says, naming off some key BID personnel, and noting that going with BID again was the right choice, even though Bienville is a different project.

The biggest difference between Bienville and LaSalle? The decision from the beginning to add a second saw line, instead of just leaving space for it. “We were going to do it eventually, so let’s just go ahead and get it done,” LeBlanc says. “This is a Gen 4 mill, we think, and we just felt like the timing was right for us.”

Though not commissioned yet, the second saw line is in place and should come on-line this summer. The mill was commissioned in phases, and with the exception of a few expected tweaks to the startup “knobs and dials,” LeBlanc says they are happy with the progress with respect to the startup curve BID presented. “Then again, our expectations were a little bit different,” LeBlanc emphasizes. “Having done this before with them.”

The Bienville PO was signed in November 2021. Leaning on previous experiences at LaSalle helped to cut some of the site prep time, including knowing how much concrete needed to be poured and how much dirt needed to be moved. LeBlanc estimates that 1.3 million cubic meters of dirt was needed to help smooth out the brownfield site and do road work, as it provided more than a few surprises in the way of organic material and bark once they really starting moving the ground.

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.