March 2024

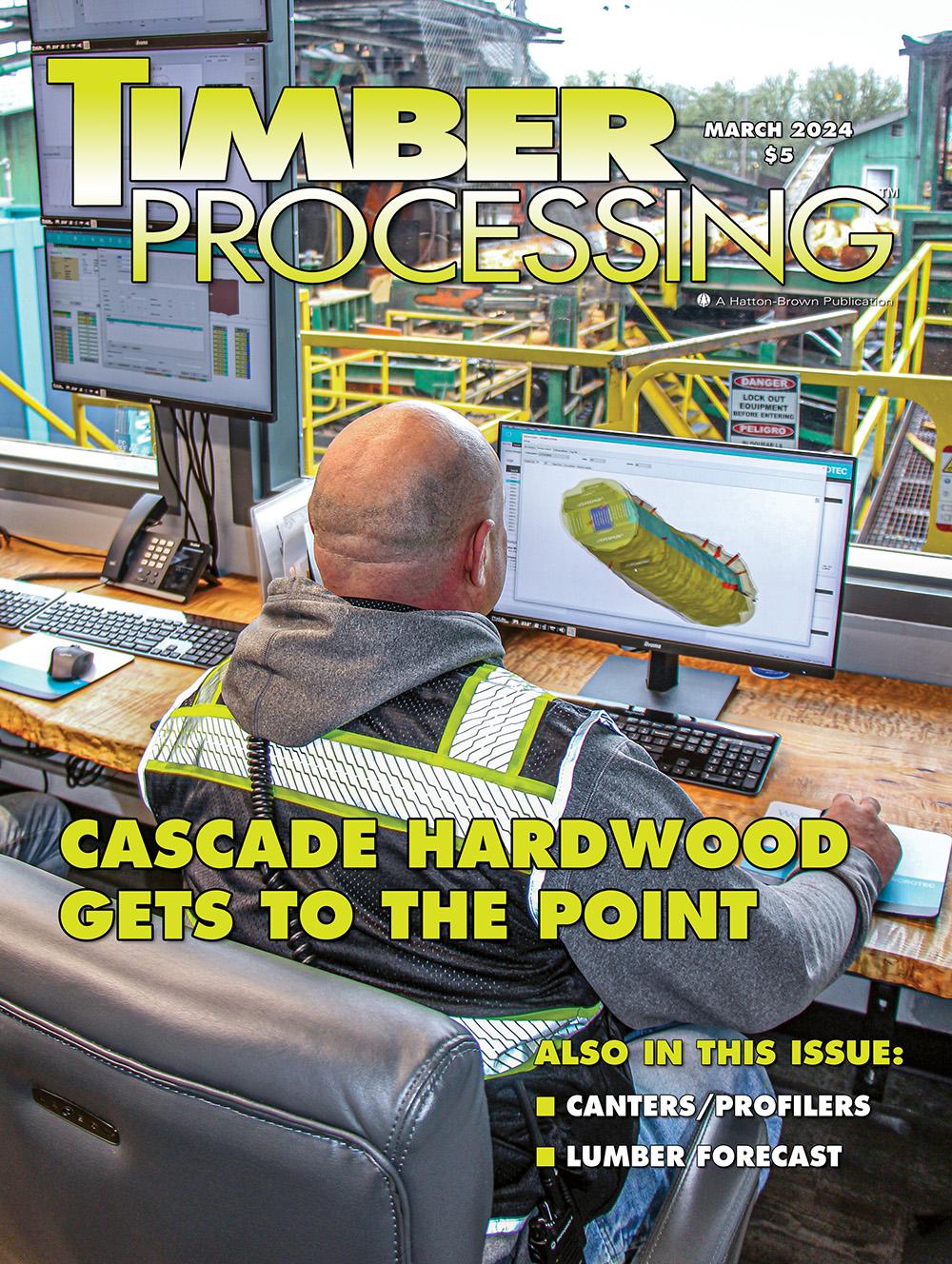

Cover: Cascade Hardwood Gets To The Point

CHEHALIS, Washington – Cascade Hardwood is taking in all of the knowledge its hardwood logs have to offer with new scanning and optimization technologies.

Inside This Issue

THE ISSUES: Which Way Are You Headed?

As I write this, spring training for Major League Baseball is in full swing and the beginning of the regular season is fast approaching. For those organizations, teams and players, it’s the last dash to fine-tune themselves before getting into the real season. I’m not just referring to player baseball skills, but also the frame of mind of the players and the management, understanding the organization’s culture and feeling good about their roles as part of it.

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- Industry Says Goodbye To Walter

- Oregon Truckers Take State To Task

- Interfor Curtails Philomath Mill

- Hasslacher Group Invests In Elements

- Boise Announces New Investments

- USDA ‘Focuses’ On Old-Growth

- Weyerhaeuser Ends Strong

- West Fraser Weighs Demand

- Roseburg Mill Donates Lumber

- Potlatch Deltic Boots Output

- Boise’s Mike Brown Steps Down In May

Canters Profilers

- Andritz

- Bid Group

- Burton

- Cone-Omega

- Linck

- Optimil

- Real Performance Machinery

- Storti

- TS Manufacturing

- USNR

Lumber Forecast 2024

How will the softwood lumber industry be impacted by developments in the U.S. residential construction market in 2024? This deep dive forecast from Fastmarkets outlines six predictions.

AT Large

- Allegheny Wood Products Closing

- Lumber Quality Workshops Announced

- Weyerhaeuser Joins With Lapis Energy

- NWH Delivers Alder Seedlings

- SFPA Expo Returns To Nashville In 2025

- Georgia Ports Approves Inland Rail Terminal

- Forest Serivces Looks At Carbon Capture

- Sustainable Report Has Mixed Results

MACHINERYrow

-

Carbotech Group Purchases Sawquip

-

Spruce Products Starts Up Continuous Kiln

-

Kiwi lumber Installs Log Sorter System

-

Equipment Innovator Paul Bell Dies At 66

-

XACTT Distributes Bigfoot CTI Systems

Find Us On Social

Knowledge Inside

Cascade Hardwood boosts grade recovery and sawing consistency with new scanning system that reveals internal log quality.

Article by Dan Shell, Senior Editor, Timber Processing

CHEHALIS, Washington – Hardwood lumber producers in many cases can see their fortunes rise and fall on the strength of their skilled sawyers, who pull the value and grade out of each log through the experience of seeing thousands of cuts and logs and “knowing” what’s on the other side of each sawline. Such sawyers have traditionally been major contributors to a mill’s bottom line. But they’re getting harder to find.

Top hardwood lumber producer Cascade Hardwood, a major red alder and Pacific maple supplier, is meeting the grade sawing challenge with investment in state-of-the-art internal log defect scanning and optimization. Scanning and optimization that actually is enhancing headrig operators’ knowledge and helping develop people for this position in a fraction of the time, delivering a higher level of quality product and consistency across multiple sawyers.

At Cascade Hardwood’s Chehalis mill, the new MiCROTEC CT Log Scanner and optimization system paired with MiCROTEC’s Logeye Stereo scanning at two headrigs is providing highest value sawing solutions informed by internal defect scanning, and the sawing function is largely automated once the operator rotates the log into position on the carriage. The mill did extensive research in 2021, pulling the trigger on the project later in the year, with startup in 2023.

Mill Manager Larry Eck says thanks to Microtec’s x-ray and computed tomography scanning system, the big benefit is now the sawyers know—really know—the knots and grade characteristics inside each log. “A trained sawyer will look at an opening face and start looking for swirls and knot indicators, and based on experience will decide how thick to go. Now, we know exactly what’s on the backside, so we can cut more grade,” he explains.

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.