JoeScan Team Expands

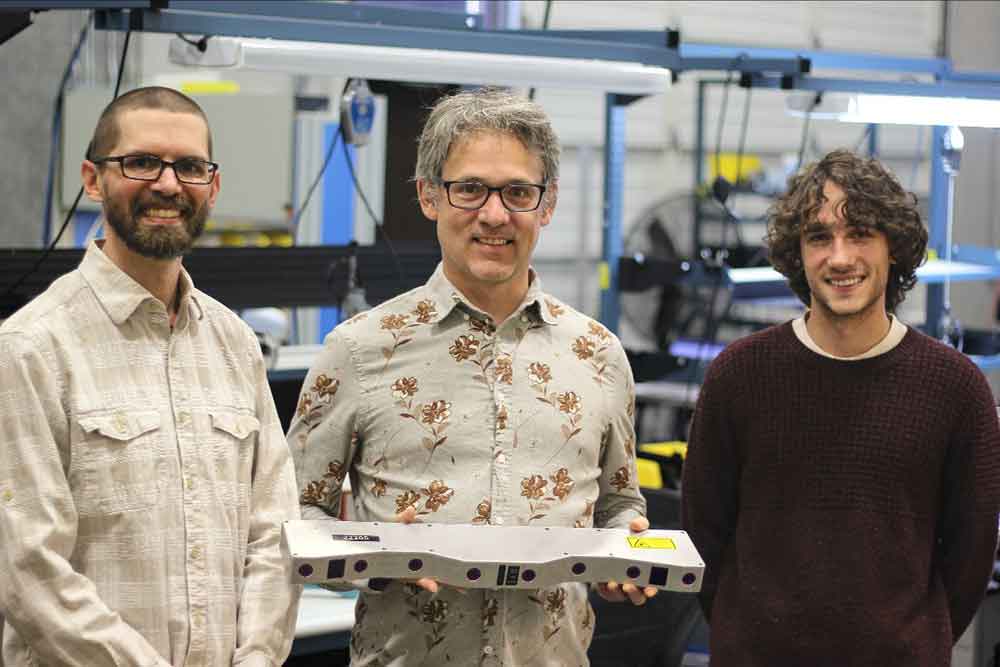

Sawmill scanning company JoeScan, founded in 2002, is once again expanding their team with the addition of two new engineers to their roster.

“We’ve seen a tremendous amount of growth in terms of sales,” says JoeScan president Joey Nelson. “So we have some additional demand on our engineers to answer support questions. But we also want to continue to develop new products and features to make 3D scanning even simpler and easier to use for sawmills.”

JoeScan has a full product development schedule underway, with a new “super snapshot” scanner model featuring 3-in. laser spacing slated for release later this year. “We designed the Z8 scanner for places in the mill where you can’t move the log or board at all,” Nelson says. “Getting data every three inches instead of every six gives you much more accurate models which means you get better solutions from your optimizer. But there are also instances when you need to run very, very fast, and the Z8’s smaller laser spacing can help you get there.”

The JoeScan engineering group is also working on a suite of software features to simplify start-ups including additional diagnostic and calibration tools.

Latest News

Study: Mountain Pine Beetle Impacts On Montana Sawmills

Study: Mountain Pine Beetle Impacts On Montana SawmillsA new study authored by the University of Montana’s Bureau of Business and Economic Research and the U.S. Forest Service Rocky Mountain Research Station examines the impact of the mountain pine beetle on costs,...

Moody’s: High Lumber Prices In 2018 To Outweigh Cost Of U.S. Duties

Moody's: High Lumber Prices In 2018 To Outweigh Cost Of U.S. DutiesSustained high lumber prices in 2018 will cover the cost of final duties imposed by the US government on Canadian lumber imports, benefiting North American producers and timberland owners, Moody's...

Thanks For Your Open Door Policy

Thanks For Your Open Door PolicyArticle by Rich Donnell, Editor-in-Chief, Timber Processing December 2017 I like to use this space at the end of the year to express my appreciation to all of the companies that opened their sawmills to our editors during the year....

Find Us On Social

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.