DECEMBER 2023

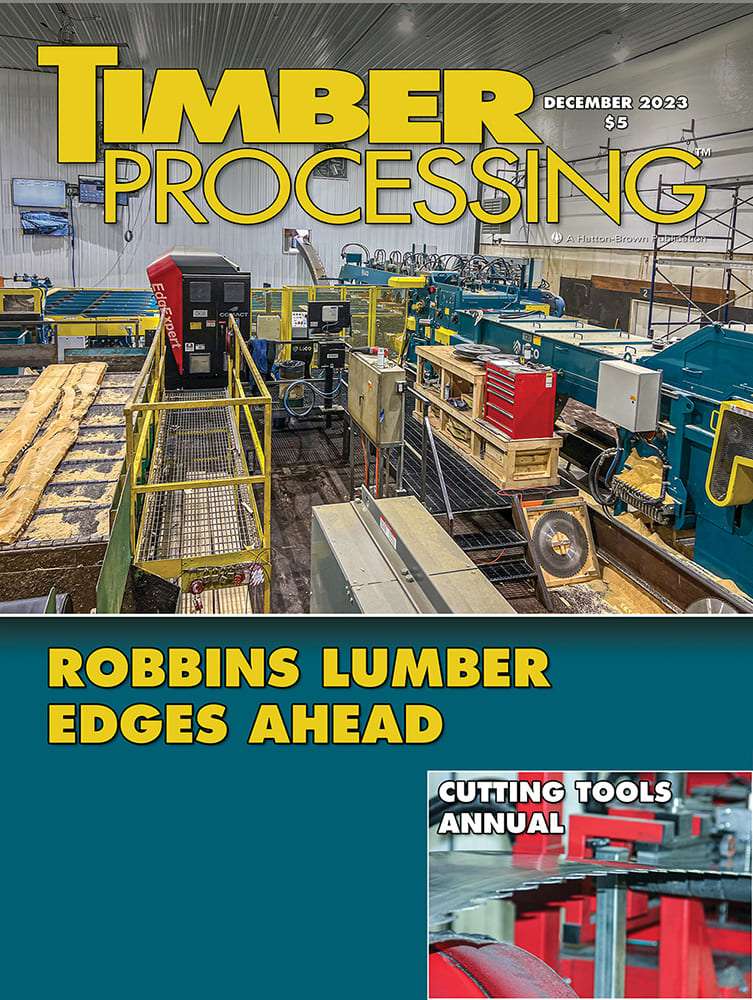

Cover: Robbins Lumber Edges Ahead

SEARSMONT, Maine – Robbins Lumber, Inc. has undergone extensive expansion over the last several years through acquisitions, upgrades and more. The growth continues with several projects at multiple sites this fall. The original Robbins sawmill, bought in 1881 and moved to its current location in Searsmont in 1969, remains the company’s headquarters and flagship operation. It is now one of four eastern white pine sawmills within a 150-mile radius in the Robbins fleet.

Inside This Issue

THE ISSUES: Sawmillers Were Skeptical But 2023 Turned Out Okay

Rising interest rates and inflation along with dips in lumber pricing had lumbermen grimacing going into 2023, even though they weren’t feeling too badly following nearly two years of exceptional profitability. But by the end of the year, everybody was feeling a little better.

READ MORE SOON

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- Patrick Lumber Manufacturing Plans Hardwood Mill

- Fiber Situation Dooms Polar

- Spray Lake Deal Is Finalized

- Pellet Purchases Bite Enviva

- Highland Plans New Pellet Mill

Filing For The Future

Through collaboration, four lumber companies are attempting to tackle a common issue: How to train a new generation of saw filers. Canfor, Interfor, West Fraser, and Weyerhaeuser have partnered with Jobs for the Future and three other organizations to develop the nation’s first national registered apprenticeship for the saw filer occupation.

By Becky Calwell, Senior Manager, Jobs for the Future

CUTTING TOOLS

EDITOR’S NOTE: The following companies submitted editorial profiles to complement their advertisements in Timber Processing December 2023.

- Andritz

- BID Group

- Burton Mill Solutions

- Colonial Saw

- Hanchett Manufacturing

- Longato

- Oleson Saw Technology

- Premier Bandwheel

- ProMac

- Vollmer

- Williams and White

PRODUCT SCANNER 10

- Drying System Selection

- Moisture Content Control

AT LARGE

- Big Creek Lumber Co-Founder Dies

- Top Wood Jobs Transfers Ownership

- Weyerhaeuser Announces THRIVE Program

- RoyOMartin Hosts Anniversary Bash

- Endowment Welcomes New Board Members

Want More Content?

Timber Processing magazine is delivered 11 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Find Us On Social

Robbins Lumber Edges Ahead

Article by David Abbott, Senior Editor, Timber Processing

SEARSMONT, Maine – Robbins Lumber, Inc. has undergone extensive expansion over the last several years through acquisitions, upgrades and more. The growth continues with several projects at multiple sites this fall.

The original Robbins sawmill, bought in 1881 and moved to its current location in Searsmont in 1969, remains the company’s headquarters and flagship operation. It is now one of four eastern white pine sawmills within a 150-mile radius in the Robbins fleet.

In 2019 the family acquired Limington Lumber, renaming it Robbins Lumber East Baldwin. On May 15 of this year they acquired two more while pine mills from Pleasant River Lumber, one in Hancock and the other in Sanford. The Sanford mill is now Robbins Lumber Sanford, while the Hancock mill was christened Robbins Lumber Downeast, so as to avoid confusion with Hancock Lumber, another well-known eastern white pine company in Maine.

“Mostly it is just about diversifying our log basket, and added production,” according to Alden Robbins, one of three company owners. Alden, 48, is the youngest among his siblings/partners: sister Catherine Robbins-Halsted, 52, and brother Jim Robbins, 50. After buying the family business from their uncle and father, the siblings represent the fifth generation of the Robbins family to run the business since its inception nearly 150 years ago.

Along with the added sawmill/planer mill capacity, Robbins added a coatings facility in the early 2000s and a biomass power plant, Georges River Energy, LLC, in 2016.

UPGRADES

The Searsmont mill was in the middle of a two-week shutdown for a large construction project when Timber Processing was on-site in early October. They were installing a new Lico Machinery highspeed edger with Comact EdgExpert edger optimizer, along with additional surge capacity decks. Robbins rented a massive Liebherr crane to pull out the old edger and put in the new; it took 16 tractor-trailers to bring in the crane.

East Baldwin is also undergoing a nearly identical upgrade as Searsmont, with a Lico edger and Comact EdgExpert edger optimizer. A new building is under construction to complement the edger. “We decided we needed to address the edger first, but we have plans drawn up to add additional bin sorting capacity and upgrade the stacker,” Alden says, adding that the company has plans for upgrades at all of the facilities, and is in the process of determining what each site needs, and when.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.