APRIL 2022

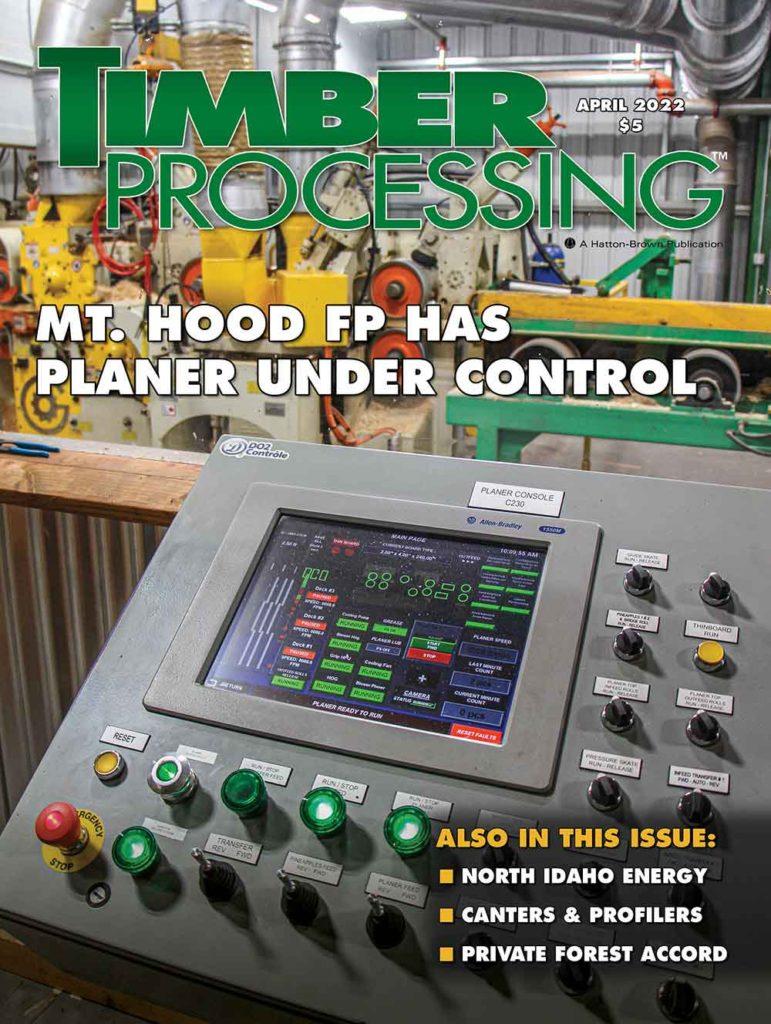

Cover: Mt. Hood FP Has Planer Under Control

ODELL, Oregon – Well known for its commitment to investing in its mills and infrastructure, the Wilkins’ family sawmills which include WKO in Carson, Washington and Mt. Hood Forest Products (MHFP) in Odell, Oregon have continued their growth in the Columbia River Gorge. Almost a year ago MHFP added a new planer mill at its innovative green Douglas fir mill south of Hood River following several key improvements in the sawmill that have boosted production and quality.

Inside This Issue

THE ISSUES: Pres-To-Logs Has History Of Its Own

The story in this issue on North Idaho Energy Logs, written by David Abbott, caught my attention at the mention of Pres-to-logs. Much of the Idaho company’s success in wood energy markets is because of its energy logs or fire logs composed of shavings and sawdust, and as the article notes they’re made with the original machines from the 1930s. The article also says the Pres-to-logs trade name is now owned by another company, which is why the Idaho operation calls them North Idaho Energy Logs.

Article by Rich Donnell, Editor-in-Chief, Timber Processing

NEWSfeed

- Oregon Agreement Said To Be Historic

- NewLife Secures Additional Funding

- Sawdust Fire Causes Big Losses

- Biomass-Based Facility Planned

Energy Makers

MOYIE SPRINGS, Idaho – Located in Boundary County, about 30 miles south of the Canadian border, the headquarters of North Idaho Energy Logs sports both the U.S. and Canadian flags. “That’s a common thing in the community,” says Clark Fairchild, co-owner of the company and General Manager at this facility. “We do pull quite a bit of shavings and sawdust out of Canada.”

Article by David Abbott, Senior Associate Editor, Timber Processing

CANTERS PROFILERS

EDITOR’S NOTE: The following companies submitted these editorial profiles and images to complement their advertisements placed in Timber Processing April 2022:

- BID GROUP

- CONE-OMEGA

- LIMAB

- LINCK

- MEBOR

- OPTIMIL

- USNR

- WEMA PROBST

MACHINERYrow

- Biewer Lumber’s New Mill Is On Pace

- Britton Lumber Announces Optimized Edger Line

- BID Group Partners With Yaskawa Robotics

- Anthony Plans New Optimization For Gangs

- Brunette Brings Portable Sawmills Into Mix

- Parton Plans Upgrade Of Edger Scanning

- Allegheny Adds New Bandmills

ATlarge

- Freres Celebrates Centennial Anniversary

PRODUCT SCANNER 10

- Handling Solutions

- Camera Connector

Find Us On Social

Mt. Hood FP Has Planer Under Control

Article by Dan Shell, Senior Editor, Timber Processing

ODELL, Oregon – Well known for its commitment to investing in its mills and infrastructure, the Wilkins’ family sawmills which include WKO in Carson, Washington and Mt. Hood Forest Products (MHFP) in Odell, Oregon have continued their growth in the Columbia River Gorge. Almost a year ago MHFP added a new planer mill at its innovative green Douglas fir mill south of Hood River following several key improvements in the sawmill that have boosted production and quality.

The new planer has made the all-green sawmill that produces 2x4s and 2x6s up to 20 ft. long an even more efficient and productive part of the family owned company’s group of facilities. During the past 10 years, output at Mt. Hood Forest Products has roughly doubled, going from 75-80MMBF annually to right around 150MMBF produced in 2021.

The past five years have been especially busy at the mill, which recovered from a January 2017 snowstorm that destroyed an outside green chain building and storage building by embarking on a series of mill improvements that same year:

- The green chain building was rebuilt along with some storage areas, and some additional paving.

- Adding a USNR multi-track trimmer fence (The WKO Carson, Washington mill has the first one USNR ever built.) and a Comact tong and dog lug loader.

- The end of 2017 saw a gang conversion that’s been a big change for the mill: Converting the existing gang from a single arbor 6 in. to a double arbor 6 in. has enabled target size kerf reductions while keeping feed speeds up.

“That’s been a big improvement for us,” says president Mike Engel. By cutting through a full 4 in. cant with the bottom saw and only touching a 6 in. cant with the top saw, the mill is able to maintain sawing and feed speeds on 6 in. cants. “We used to have to slow down with the single arbor, but now we can keep up the same speeds on four- and six-inch,” he adds.

Want More Content?

Timber Processing magazine is delivered 10 times per year to subscribers, who represent sawmill ownership, management and supervisory personnel and corporate executives.

Newsletter

The monthly Timber Processing Industry Newsletter reaches over 4,000 mill owners and supervisors.

Subscribe/Renew

Timber Processing is delivered 10 times per year to subscribers who represent sawmill ownership, management and supervisory personnel and corporate executives. Subscriptions are FREE to qualified individuals.

Advertise

Complete the online form so we can direct you to the appropriate Sales Representative.